In this series, we discuss some of the most frequently asked questions we receive about LEDs. In this post: the basics of LED life from Outreach and Training Specialist Tom Littrell.

You can’t measure an LED lifetime in the same way as an incandescent light bulb. Instead of burning out, a properly cooled and powered LED will fade very slowly over time, lasting tens of thousands of hours.

So rather than measuring an LED’s life by when the emitter completely burns out, LED users have decided that once an LED device drops below some threshold – usually (but not always) 70% brightness – the LED can be considered a “burn-out.” This brightness threshold is generally expressed as ‘L70’ in specifications.

Testing determines how long it takes an LED to reach L70. That time is written as ‘B50’ if 70% brightness is reached in 50,000 hours. Or around 5 ½ years if you’re interested. The L70 threshold – along with the amount of time it takes to reach that threshold – is called an LED’s “lumen maintenance” specification. It can be written ‘B50 L70.’

In order for a lumen maintenance specification – or any specification – to be usable, everyone has to use the same procedure for testing. LM-80 and LM-84 are the primary testing protocols for determining lumen maintenance. LM-80 applies to individual emitters and arrays, while LM-84 applies to complete luminaires. In theory, it would make sense if every LED product underwent this testing—but in practice, this is no easy task.

Testing takes patience

To complete testing, the emitters or fixtures have to be powered in strictly specified conditions for multiple 1000-hour cycles. In total, LM-80 and LM-84 testing require a minimum of 6,000 hours of real-time testing, with status checks every 1,000 hours. That’s just over eight months!

A given LED emitter or fixture might take 50,000 hours to dim to 70% brightness. Therefore, it takes 5½ years (50,000 hrs.) of testing to determine this? Not feasible. Reliable standards – TM-21 and TM-28, for example – create formulas to extend actual testing mathematically to achieve reliable predictions of long-term life.

But even with this ability to predict lumen maintenance virtually, it still takes a long time. For example, an emitter rated for L70 at 50,000 hours requires almost a year of real-time testing to determine that it meets that specification.

This whole process is obviously time-consuming and expensive. While large emitter manufacturers do LM-80 testing for most of their LED products, most fixture manufacturers can’t spend the time or money on LM-84 testing.

Generally, fixture manufacturers base their L70 rating on the LM-80 data provided by the emitter manufacturer. However, the testing protocols for emitters do not inherently translate to how they will perform in a complete fixture. A fixture manufacturer may under-cool and over-power the emitters to cut costs and appear brighter out of the box. In that case, the fixture will never reach a stated 50,000-hour L70 life.

What ETC is doing

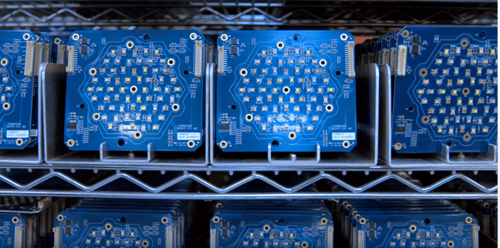

Because we at ETC are committed to building long-lasting, quality lighting products, we are now engaged in LM-84 testing on many of our most popular LED products. The results are in for four ETC LED products.

ColorSource Spot and Source Four LED Series 2 performed at higher than industry norms with a predicted L70 rating of 54,000 hours. And ColorSource PAR and ColorSource Linear bettered that at greater than 55,000 hours.

Finally – duty cycle. Fixture usage varies greatly across venues so there is no accurate way to determine a duty cycle for a “typical” LED stage lighting fixture. However, if we ballpark that a typical fixture might be on at full for two hours a day, every day, 365 days a year, L70 at 54,000 hours would be reached in 74 years. That’s quite a lifetime for a fixture!

To learn more about L70 ratings, watch the video from ETC below.