We each have a past. Some more shady than others. And when it comes to the LEDs we use in ETC fixtures you might be surprised to learn where each comes from. Surprisingly, not a single one was created with theatrical lighting in mind.

They’re each repurposed from a variety of industries around the globe, most of which are completely unrelated to stage, school, worship, and hospitality.

Rob Gerlach is one of the original founders of Selador, the company responsible for a large majority of ETC’s original LED technology. Because of the in-depth work Selador had done with LEDs early on, ETC purchased the rights to their fixture technology in 2009. When asked what he knew about other industries using LEDs in their products, Rob went way back for a fantastically fascinating history lesson.

The following is a retelling of colored LED history from Rob Gerlach himself.

——————————————————————

Lumileds is a company that was founded in the early 2000s to create high-brightness LEDs. They released their first LED package, Luxeon 1, at the Lightfair trade show in May 2001. It was at that same Lightfair that Novella Smith and I first met and started having the early interactions that would eventually lead to Selador. It was a very fateful trade show.

Luxeon 1 was a whopping 1-Watt LED package… quite unimpressive by today’s standards. It was bulky, inefficient, and produced a lot of heat for its output, but it represented a huge leap forward for LEDs in illumination. As far as I know, nobody else was making an LED anywhere close to this bright or this suited for use in illumination at that time.

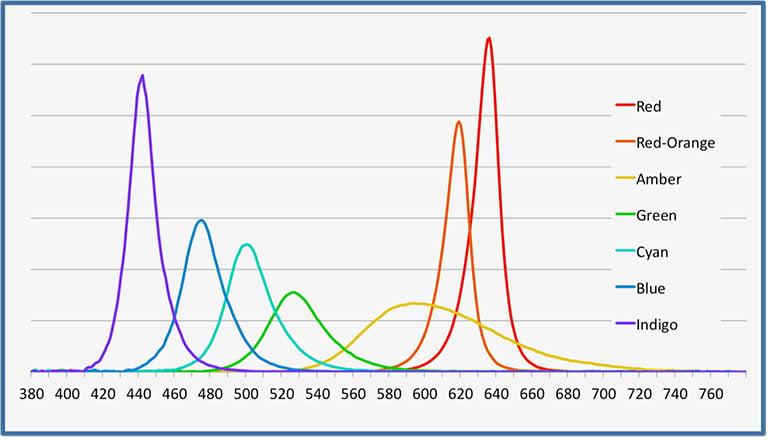

When Luxeon 1 was released, it was available in seven colors: red, red-orange, amber, green, cyan, blue, and royal blue (which is what we at ETC call indigo). It was also offered in a very limited range of white. There were specific reasons behind the selection of those seven colors. One of which had to do with the technology behind the LEDs themselves. There were (and still are) two, primary chemical formulations that are the basic foundations for all LEDs used in lighting.

Chemical formulations of LEDs

One formulation, aluminum indium gallium phosphide (AlInGaP), produces a range of colors in red, orange, and amber. It can produce some colors outside this range, like yellow and lime-green, but these colors are ridiculously less bright and less efficient. If you were to plot the range of colors AlInGaP can produce across the visible spectrum by relative brightness and efficiency, it would be a sharp curve, with peak output at red, dropping way down at yellow.

Today we use a different technology for our amber and lime emitters, but in the early days, those products weren’t available. Selador had to use many times more amber emitters in fixtures versus red and other colors, in order for the output to balance out. There are still many more amber than any other color in our fixtures, but it’s not quite as big of a challenge today as it used to be.

The other formulation, indium gallium nitride (InGaN), produces a range of green, cyan, blue, royal blue, violet, and UV. It also has a curve of peak output, with highest efficiency in the indigo-violet range and dropping down toward green. Neither AlInGaP nor InGaN is capable of producing yellow or lime emitters with useable output, and InGaN green is problematic. We have to use relatively more green emitters in our fixtures than we’d prefer, because the technology is just not efficient enough in that color range. The industry calls this phenomenon the “Green Gap.”

Between the two, InGaN has seen much more development over the years, because InGaN is the basis for virtually all white LEDs on the market. It is royal blue (aka indigo) that is used as the “pump” in white LEDs, which excites a layer of phosphors that down-converts a portion of the light into longer wavelengths (green, yellow, orange, and red) to produce a combined output that appears white. In other words, white LEDs are always indigo plus a layer of phosphors.

Yes, but where are they used?

Besides technology, there were economic reasons for focusing on the original seven colors of Selador. Several other industries were already using them which made them easier to get. Here are some of the markets each of the colors served.

- Red – traffic signaling, industrial

- Red-Orange – automotive, medical, industrial

- Amber – automotive, traffic signaling

- Green – RGB applications, industrial signaling

- Cyan – marine and airport marking, “green” traffic lights/signaling

- Blue – RGB applications, law-enforcement and emergency signaling

- Indigo – medical/dental, white-light technologies

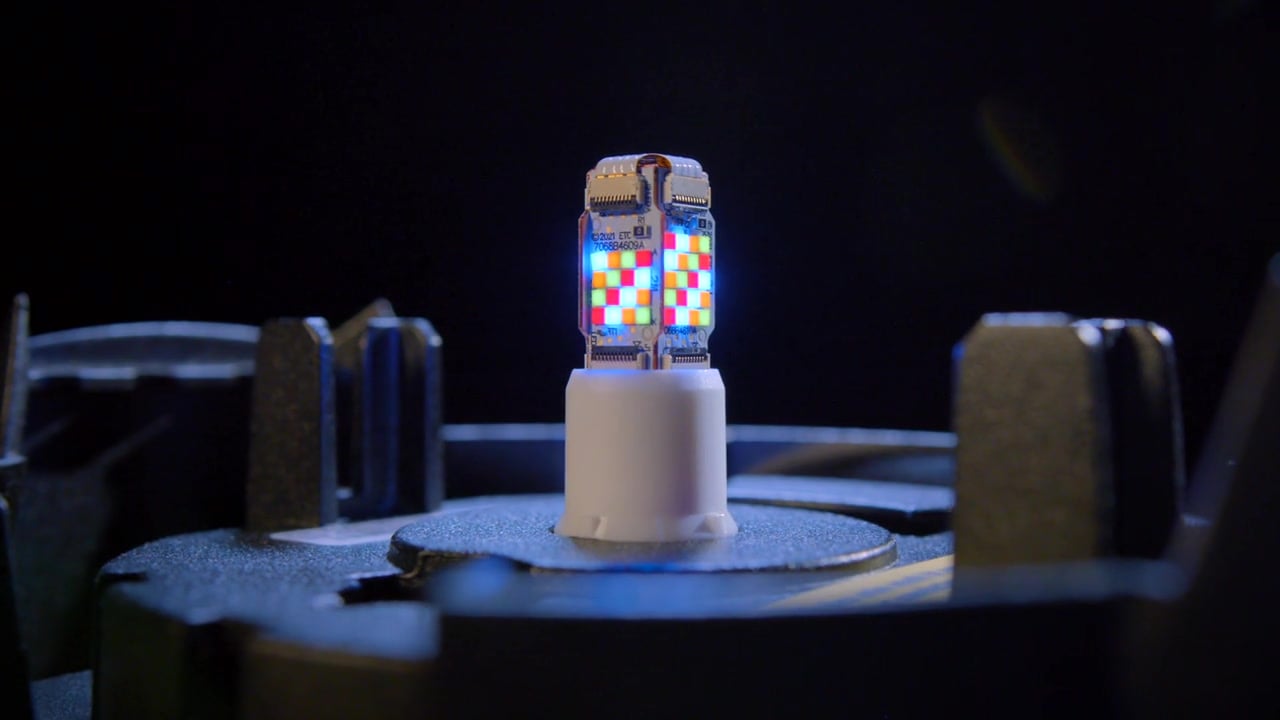

Because Luxeon 1 was the only high-brightness LED at the time, and because it was offered in seven distinct colors, Selador chose the Luxeon as the basis of the original x7 system. The success of the x7 system however, is not solely dependent on the fact that there are seven colors, but that we’ve combined them in a specific ratio to optimize the balance of colored and white-light output. Although the colors in the mix have expanded over the years and are now specialized for specific lighting tasks, ETC still uses the x7 approach, which remains unique among color-mixing fixtures worldwide.

From the very beginning, Selador developed a good relationship with Lumileds, fostering friendships with key leaders within the organization. It gave us access to information and a voice within the company that was far greater than our sales alone could have justified. As early as we could start asking, we began begging and pleading for a lime-green emitter to fill the “Green Gap.” The answer was always that Selador was the ONLY company asking for this color, which made it economically unreasonable for Lumileds to produce it, but in a back-room lab, we saw early prototypes of what would eventually become the lime we use now.

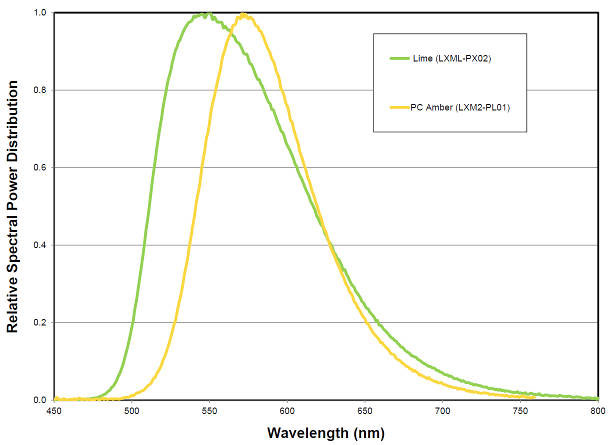

As Lumileds LED packages got brighter and more efficient, the first major advancement was the release of a phosphor-based amber. This product came out just about the same time that ETC acquired the Selador product rights in 2009. Phosphor-converted (or “PC”) amber uses exactly the same technology as white emitters – an InGaN indigo pump LED with a phosphor layer over it – only the phosphor layer is just amber, not a mix of green, yellow, etc., and the phosphor converts essentially all the indigo pump light into the longer wavelengths, as opposed to white LEDs, which allow some of the original indigo light to pass through as part of the white-light mix. InGaN-based PC amber is far brighter, more efficient, and more stable than AlInGaP amber. It’s basically now the standard for amber LEDs.

“Even Costco Christmas lights use PC amber now, but it was still primarily automotive and, to a lesser degree, traffic signaling that drove this development.”

Finally, it’s time for lime!

A few years after amber, Philips introduced its Hue line of color-changing, smart-home lighting products for consumers. Rather than traditional RGB, these products use red-orange, indigo, and lime for their mix. Lime works just like PC amber. It’s an indigo pump and a layer of lime-green/yellow phosphors that convert all of the indigo light. For Philips Hue products, it means that they have a pretty limited range of saturated colors, but they are able to do white, particularly warm white, far more beautifully and convincingly than any RGB mix can do. It was actually a very smart way to go. AND … it gave Lumileds a reason to produce lime – FINALLY!

I vividly remember the day I sat at Lumileds headquarters and their VP of Color Products brought me a little demo box with a lime emitter and told me our dream had come true. It took ETC a little while to find the right way to introduce lime into our product lines (and no small amount of convincing on my part) but lime was a major deal for our industry, as we know. Of course, it didn’t take long for our competitors to pick up on the huge advantages of lime in a color mix, but we were the first.

————————————————–

As for the future of ETC LED fixtures, there’s no sign of slowing down. New advances in technology are on the horizon and thanks to our always-inquisitive team at ETC, color temperatures, custom mixed arrays, and fixture offerings continue to be on the cutting edge of advancement.

To read more about Lumileds, you can check out their website at https://www.lumileds.com