As ETC expands, so does its workforce. Over the past five years, the company has nearly doubled the number of employees around the world. This means more assemblers, engineers, custodians, developers, marketers, factory planners, and shippers. So many interesting and intelligent people come together each day to bring you the products that keep your theatres, schools, hotels, and arenas running.

At ETC we have begun to embrace industrial design as an integral part of the research and development process. Our designers are often responsible for the appearance, functionality, and manufacturability of ETC and High End Systems’ products. They champion the voice of the user throughout the development process.

Earlier this year two of our designers Jon Rasche and Zack Zlevor were published in Innovation Magazine. This periodical by the Industrial Designers Society of America is the most popular industrial design magazine in the country. Here is their article.

————————————————————–

Computational Ideation: Generating A New Starting Point

Jon Rasche, IDSA & Zack Zlevor, IDSA

INNOVATION Summer 2019

Vol. 38 No. 2, p. 48

The role of industrial design is rapidly evolving as commercial interest in truly designed products grows. It is critical that designers rethink and implement new tools that allow for the most creative freedom while maintaining increasingly tighter deadlines and greater project involvement.

As a team of two designers embedded within a corporation of 1,200 employees, time is often our biggest limiting factor while we navigate the development of simultaneous products. The two of us have wildly different talents and preferences, but we both firmly believe that iteration is key, and that design without diligent exploration is a snipe hunt or design-by-ego. Initially, in our mini-design studio within the company, we would leverage every tool in our wheelhouse to try to realize and deliver fully explored, designed and vetted concepts to engineering, all while adapting to the often changing scope and mechanical requirements. We quickly found that our mutual appreciation for wide-net iteration was at odds with our workload and caused a bottleneck. Our current tools, whether CAD, physical mockups or digital sketching, still proved fruitful for quick thought generation and bold ideas. We yearned for a magic wand that would let us ideate, develop, edit and demonstrate ideas at greater quantities and qualities.

DEVELOPING AN ALGORITHMIC APPROACH

The task set before us was to create a new brand image and physical design for a series of lighting control consoles for High End Systems, an ETC Company. We knew we wanted to push form in a unique direction that broke the status quo of industrial design within our company.

After noticing the incredible generative works in the field of architecture, such as Zaha Hadid’s Guangzhou Opera House in China and Moshe Safdie’s ArtScience Museum in Singapore, we questioned how we could implement an algorithmic approach to our design practices that would allow for rapid iteration and model generation, while avoiding blatant parametricism and still creating varying appropriate brand images that were unique yet honest.

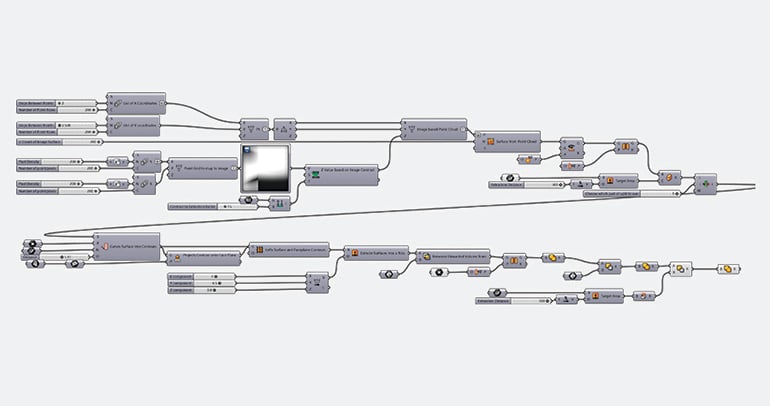

To do this, we worked closely with our key stakeholders and established baseline brand aesthetics for High End Systems and this product line. After delivering a basic representation of our intentions in simple, manually produced CAD models, we further developed the aesthetic by leveraging the computational power of Grasshopper.

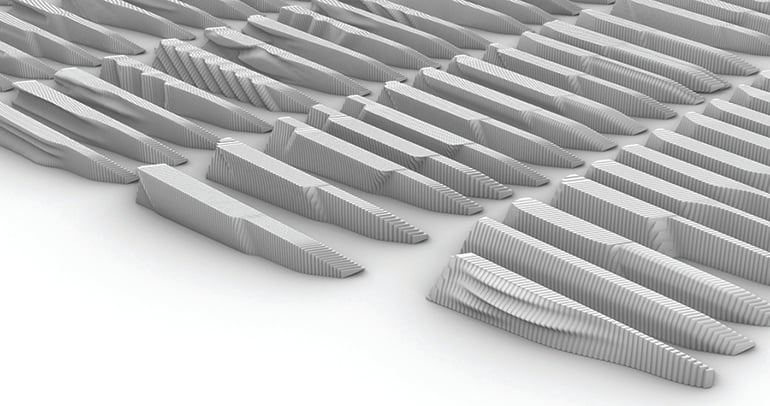

Taking cues from the architectural industry, we developed a custom-made generative algorithm script that empowered us to realize full CAD models using simple sketches. The process begins by creating a 2D array of points. Grasshopper then takes our drawing and divides it into samples taken at intervals across our sketch. The contrast value of each sample is assigned to the Z value on our 2D array, bursting it into 3D. This creates a rippling sea of points to which we can conform a polysurface. The result produces a native Rhino polysurface that can be manipulated the same as any other Rhino object and can be edited more fluidly than a Solidworks surface.

Since Grasshopper can parametrically perform the same operations that Rhinoceros can, we wondered how we could take the visual code further to fully realize each surface into a solid part. Using parametrically defined part shapes, we were able to dynamically trim and solidify our generated surface into our desired part shapes for our lighting console.

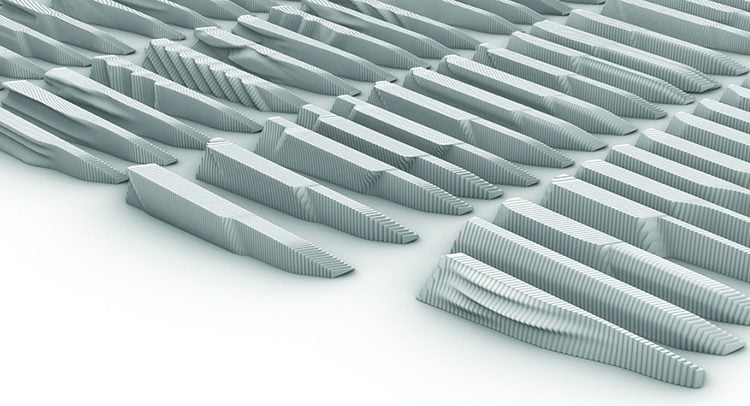

Adding another block of code applied an additional branding aesthetic to the part. This worked by segmenting our part body into striations, extruding them at varying angles, lofting to protect draft angles and merging the new solids to create a single solid part. All these trims, angles and extrusions are fully parametric, which allowed for changes to happen in real-time, as well as down the project timeline.

This sketch-to-CAD process (SKAD) allowed us to distill our ideation process into almost impressionistic sketches, saving tons of time while increasing tenfold the speed at which we could get ready-to-render or 3D print solid-model concepts. We were producing hundreds of compelling and meaningful concept models a day.

From here, we worked closely with our key stakeholders, presenting concepts at a rate that was previously never seen. Once we demonstrated that we had full control over our algorithm, our stakeholders thoroughly enjoyed being part of the design process. More importantly, we designed a tailored solution for them while maintaining creative control.

A NEW TOOL FOR THE FUTURE OF DESIGN

While our industry continues to evolve, it is important that we as designers not only dynamically adjust to our surroundings but also trailblaze. If the last leaps in methodology were CAD and rapid prototyping, our next leap forward will be leveraging computational design to increase our reach. Recent architectural design has proven to us that computational designs can be bespoke, unique and fresh, a hard find in this information-overload and copycat-filled era. It is time that this new form of design reaches the masses via consumer industrial design.

As the trend of computational design and the technology grow, we might have to question preconceived roles of the designer and the consumer, because mass-scale customization is quickly becoming a reality. This could be a new renaissance of design that involves the user to the highest degree. Computational design will bring an explosion of new patterns, textures, and forms, akin to the organic design era of the 1930s–1960s.

Designers will always be learning how to better harness the power of computational design. While we do so, it’s important that we remind ourselves it is OK to automate a portion of the creative endeavor if it opens doors for further growth in other portions. Tools like Grasshopper not only greatly increase the rate at which we can generate complex concepts, but they also give us the opportunity to spend even more time diligently critiquing our own work and honing our designs’ quality and details. With designers able to iterate faster and further on designs, the growing importance and appreciation of properly industrial designed products will only continue to grow.

We are early in our careers as industrial designers, and while we value tradition, we strive to innovate our own processes and embrace emerging technologies. Industrial designers have always championed the user, studying their problems and solving them using superior design solutions. What if we as designers need to redesign the industrial design process?

We believe computational design can be one of the new tools we leverage to better fulfill our function as designers. Computational design allowed our small team of two to increase our productivity tenfold. We feel a significant shift in the way our company approaches design and how design is approached globally. If a new era of design is quickly approaching and bringing unknown challenges, we need to keep asking what new tools are at our disposal and how can they help us improve as designers.

— Jon Rasche, IDSA

— Zack Zlevor, IDSA

Jon Rasche has a Master of Science in engineering from Imperial College London and a Master of Art from the Royal College of Art in innovation design engineering. Zack Zlevor has a Bachelor of Fine Arts in industrial design from the University of Illinois at Urbana–Champaign. They currently head up the industrial design department at Electronic Theatre Controls (ETC) in Madison, WI.